Helistage meile

+86-19858305627

Saatke meile e-kiri

sales@maple-machinery.com

Raskeveokite masinainvesteeringute valatud komponendid Tootjad

Meie tehas pakub liivavalu, suletud stantsi sepistamist, avatud stantsimist jne. Ekstreemne disain, kvaliteetsed toorained, kõrge jõudlus ja konkurentsivõimeline hind on see, mida iga klient soovib ning seda saame ka teile pakkuda. Võtame kõrge kvaliteedi, mõistliku hinna ja täiusliku teeninduse.

Kuumad tooted

Rasketööstuse terase liivavalu osad

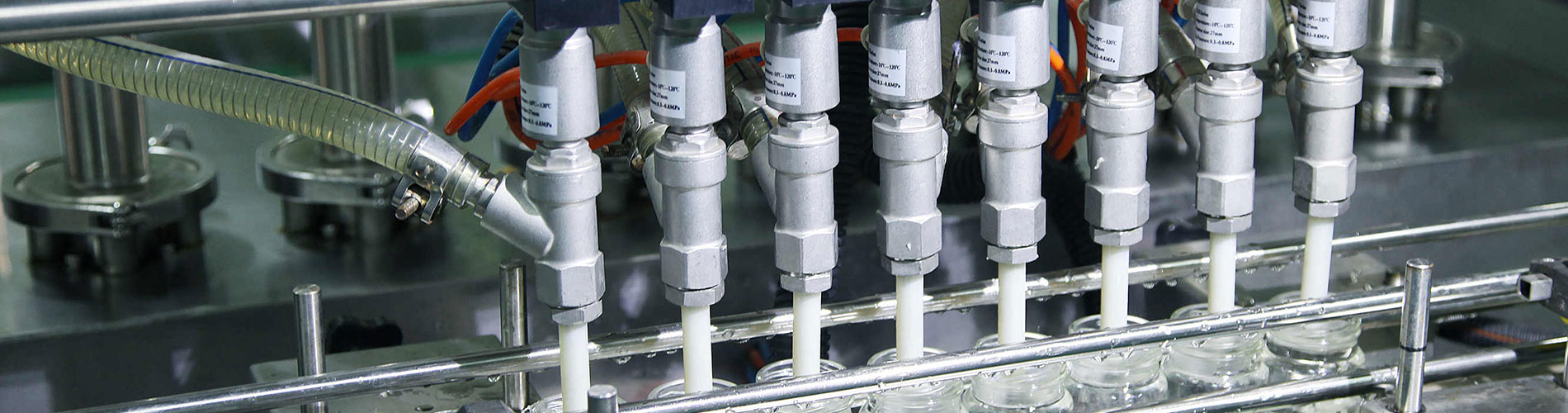

Vahtramasinad on spetsialiseerunud kõrgekvaliteedilistele rasketööstuse terasliivavalu osadele ja pakuvad kvaliteetseid mahulisi tootmistellimusi ja üksikute esemete tootmist. Valukoja põhimaterjal on erinevat sorti teras. Kvaliteetsed valuvormid võimaldavad järgnevat töötlemist minimaalse varuga. Valatud teras pakub keeruka geomeetriaga tooteid ja on seetõttu sageli ainus viis keeruka struktuuriga metalltoodete valmistamiseks.Hüdraulikasüsteemi terasest täppisvalu osad

Vahtramasinatel on tugev tehnoloogia arendus- ja innovatsioonivõime, et vastata hüdraulilise süsteemi terase täppisvalu osade tootmisnõuetele. Oleme teinud aktiivset koostööd silmapaistvate rahvusvaheliste ettevõtetega, et ehitada hüdraulikasüsteemi täppisvalu osade partii konkurentsieelistega. Ettevõttel on tugev tehniline jõud, täielik professionaalne varustus, range kvaliteedikontroll. Meie ettevõte teab hästi, et tootekonkurents põhineb uute toodete väljatöötamisel, inimeste loovusel ja kvaliteedikontrollil, mistõttu oleme konkurentsivõimelisi tooteid arendanud läbi süstemaatilise juhtimisstrateegia ja tehnoloogia akumulatsiooni.Hüdraulikasüsteemi rauast liivavalu osad

Maple Leaf Machinery Co., Ltd. toodab hüdraulikasüsteemi rauast liivavalu osi ja oleme viimased 15 aastat oma talenti täiustanud. Kasutame oma teadmisi, et anda edasi parimaid hüdraulikasüsteemi rauast liivavalu osade tavasid ja tehnikaid ning võtta kasutusele uusimad edusammud valuprotsessides. Ettevõte keskendub peamiselt liivvormivalamisele, kestavalamisele ja vahavalule ning laiendab pidevalt tugirajatisi, tehnoloogiat, seadmeid ja teenuseid.Toidutööstuse masinate terasest sepistamise osad

Maple machinery investeerib pidevalt meie inimeste, protsesside ja masinate arendamisse, et saavutada meie arengueesmärke. Investeeringud ja innovatsioon on taganud toiduainete töötlemise masinate terasest sepistamisosade taseme. Tänu pidevale sisemisele arengule ja täiuslikkuse poole püüdlemisele oleme klientide poolt tunnustatud.Klapi terasest sepistamisosad

We at Maple machinery guarantee the quality and impeccable service of every Valve Steel Forging parts. We strive for excellence every day, using all of our expertise and tremendous commitment to ensure maximum efficiency. We aim at innovation to create a better future and bravely face every new challenge. Product Introduction The different Forging techniques offered by Maple machiney Forging solutions enable us to forge the different Valve Steel Forging parts of valves all of which are designed to the customer's requirements and are also checked and verified in a simulator before forging. The resources and skills of our staff enable us to forge any type of material that is processed on our heat treatment equipment and completed after conducting final destructive and non-destructive tests. They are provided on delivery terms agreed with the customer and include all required documents and certificates. 2. Product Parameter (Specification) Item Valve Steel Forging parts Roughness Ra 1.6 Tolerance ±0.01mm Material Alloy Steel Certification ISO 9001:2015 Weight 0.01-60KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Closed Die Forging Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Services for Valve Our Valve Steel Forging parts have a worldwide reputation for their high quality and reliability. With our state-of-the-art testing laboratories and highly qualified workforce, we combine the highest standards of technology, quality and productivity. Accurate delivery time, fast service, we get the customer's praise. 4.Supporting Service for Valve parts As mentioned above, in order to work in adverse conditions, the performance of the Valve Valve Steel Forging parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Agricultural Machinery We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Valve Steel Forging parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for the Valve We have manufactured a wide range of Valve Steel Forging parts. The following are typical products: Valve joint, Ball valve body, Gate valve body, Choke valve body,Beer valve body,Purification water brass,Hybrid valve, .... 6. Why Closed Die Forging Compared with casting, forging has its special advantages: 1. In the case of the same material, the mechanical properties of forgings are better than those of castings. 2. The forgings strength is higher and the fatigue resistance is stronger. 3. The forgings has better compactness. 4. There are no internal defects and surface defects. 5. Fast production speed, high efficiency, suitable for mass production of products. 6. The product quality is stable.Ehitustehnilised terasest kadunud vahavalu osad

Meie lugupeetud klientide maksimaalse rahulolu saavutamiseks oleme pühendunud esmaklassiliste ehitusterasest kadunud vahavalu osade pakkumisele. Täpne disain ja võimas arendus terase-, materjali- ja igapäevaseid tarbekaupadega tegelevatele ettevõtetele, et pakkuda sobivat tootmisvalikut. Need tooted kasutavad uusimat uuenduslikku tehnoloogiat ja on toodetud rangelt kooskõlas tööstusharu standarditega. Lisaks saab neid muuta vastavalt kliendi konkreetsetele eeldustele.

Saada päring

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy