Helistage meile

+86-19858305627

Saatke meile e-kiri

sales@maple-machinery.com

Kulinaariamasinate terasest valatud komponendid Tootjad

Meie tehas pakub liivavalu, suletud stantsi sepistamist, avatud stantsimist jne. Ekstreemne disain, kvaliteetsed toorained, kõrge jõudlus ja konkurentsivõimeline hind on see, mida iga klient soovib ning seda saame ka teile pakkuda. Võtame kõrge kvaliteedi, mõistliku hinna ja täiusliku teeninduse.

Kuumad tooted

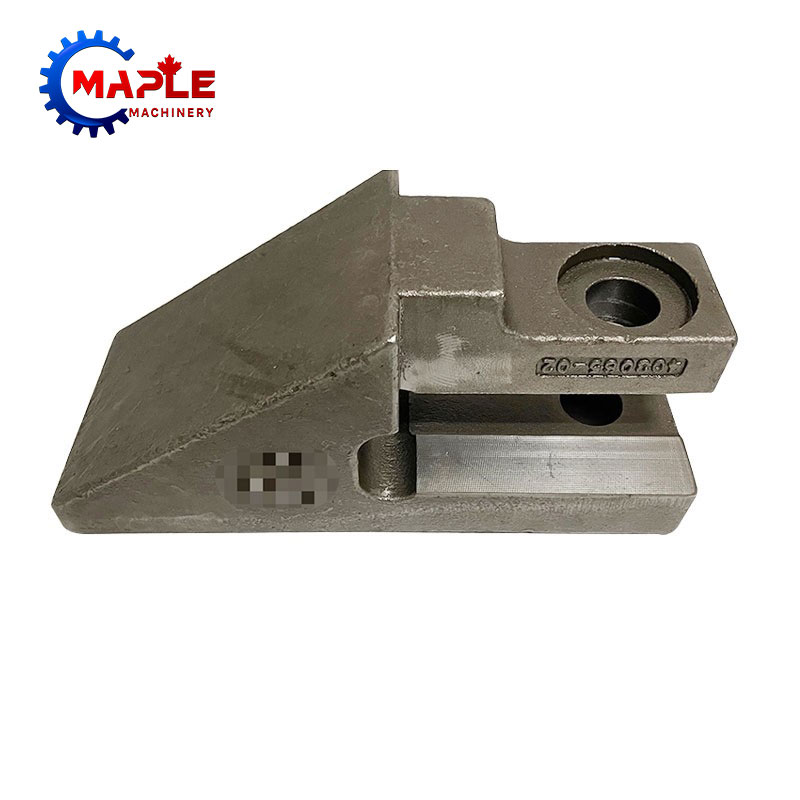

Kiirteetööstuse terasest kadunud vahavalu osad

Maple machinery has a number of casting plants, with strong processing capacity Specializing in the production of carbon steel, alloy steel, stainless steel, high temperature alloy and other wax lost casting parts and machining parts. Maple's superior quality of Off Highway Industry Steel Lost Wax Casting Parts attracts equally excellent customers, enabling our products to serve various machinery industries. 产品内容 Off Highway Industry Steel Lost Wax Casting Parts Product Introduction Off Highway Industry Steel Lost Wax Casting Parts is a product that Maple machinery has been doing. Lost wax casting is now called investment casting. It is a precision casting process with little or no cutting. It is not only suitable for precision casting of various types and alloys, but also produces castings with higher dimensional accuracy and surface quality than other precision casting methods. In order to meet the needs of different customers, we use two kinds of wax, namely yellow low temperature wax and green medium temperature wax. 2. Product Parameter (Specification) Item Off Highway Industry Steel Lost Wax Casting Parts Roughness Ra 1.6 Tolerance ±0.01mm Material Casting Steel/Casting Iron Certification ISO 9001:2015 Weight 0.01-5000KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Sand Casting Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Services for Off Highway Industry Maple machinery has been increasing its manufacturing capacity for Off Highway Industry Steel Lost Wax Casting Parts for many years. Provide high quality Off Highway Industry Steel Lost Wax Casting Parts for our machining operations to meet and satisfy customer needs. We are able to process different types of castings, including: pressure die casting and sand castings. We assist our customers to select the most appropriate casting type according to the required volume and complexity, providing the most cost effective solution. The railway sector provides a crucial network for transport and distribution. It needs cost-effective and long-lasting equipment that is dependable for the range of applications. The railways, from freight to passenger, need different castings for various applications. Maple Machinery carries extensive experience to create steel castings and iron castings in varying sizes, shapes, and materials that are precise, strong, and durable. We manufacture a wide range of castings and forgings for railway infrastructure and transportation equipment. 4.Supporting Service for Off Highway Industry parts As mentioned above, in order to work in adverse conditions, the performance of the Off Highway Industry Steel Lost Wax Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Off Highway Industry parts We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Off Highway Industry Steel Lost Wax Casting Parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for the Off Highway Industry We have manufactured a wide range of Off Highway Industry Steel Lost Wax Casting Parts. The following are typical products: Coupling components, Centre plates, Bearing brackets, Rail wheels, Wheel hub, Base plate, Axle boxes, Yokes, Pedestals, Hinges, Tie plates, Side jaw clip, and Joint bar. 6. Why Sand Casting Sand casting is an ancient casting process where the metal parts are molded by pouring metal into a hollow cavity. The mold-based manufacturing process is used to make castings with materials of iron, steel, and Aluminum. Casting-based manufacturing includes several steps and can create a wide range of shapes and sizes for metal products. The process begins with the making of a mold pattern and a gate system with the exact size and shape of the required part. The temperature required depends on the metal as some metals take a long time to heat and melt. Maple Machinery has continuously upgraded its Sand-casting equipment and refined the casting process. The aim behind this is to use only the advanced casting technology for its Sand-casting operations. Each step follows the customer’s drawings and instructions to deliver precise solutions.Klapi terasest liivavalu osad

Oleme tootja, kellel on laialdased kogemused klapiterasest liivavaluosade valmistamisel ja usume, et kvaliteetsed vormid on valuprotsessi kõige olulisem komponent. Meil on 2 täiskohaga mustritegijat, kellel on üle 60-aastane tööstuskogemus ja suurepärased suhted mõne Põhja-Ameerika kõige arenenuma Valve ettevõttega. Ükski projekt pole Maple masinate jaoks liiga keeruline. Kulunud/vananenud osa pöördprojekteerimisel, 2D-visandite põhjal mustrite loomisel või uusimate 3D-mudelivormingute alusel on meil võimalus võtta teie ideed ja kujundused ning muuta need valanditeksEhitustehnilised roostevabast terasest valuosad

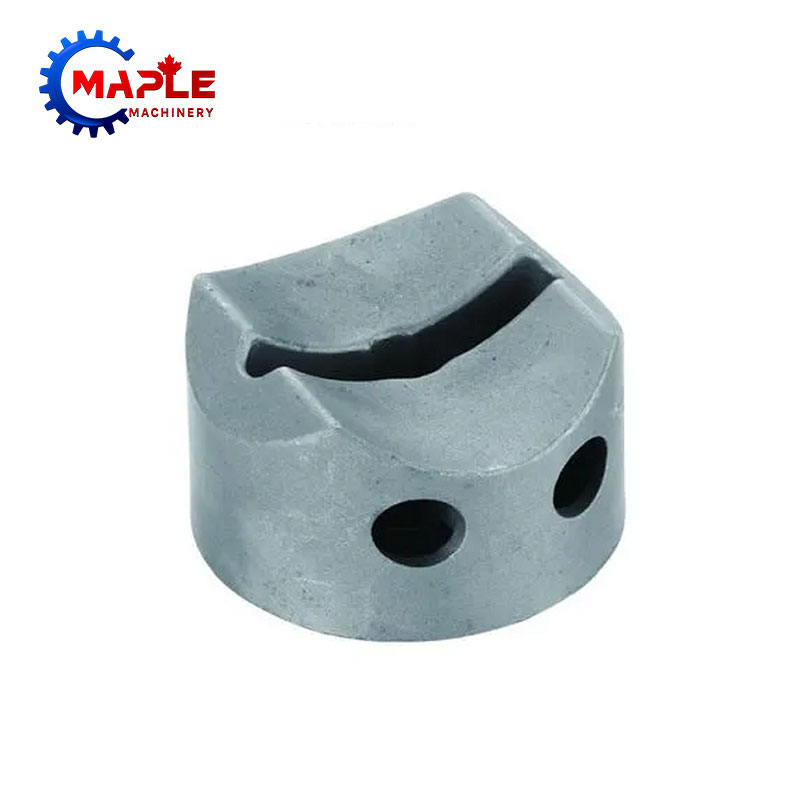

Maple Machinery on tsiviilehituse roostevabast terasest valuosade tarnija, kes toodab keerulisi valandeid äärmiselt suure täpsusega, kasutades "kadunud vaha" meetodit. Selle üldise lähenemisviisi tõttu on meie inseneridel tootekujunduses ja materjalide valikus märkimisväärne vabadus. See tähendab, et teiega konsulteerides saame toota parima valandi, mis vastab täpselt teie soovidele ja nõuetele. Maple machinery on teie arenduspartner edukaks valamiseks, eesmärgiga toota vastastikusel konsultatsioonil parim valutoode.Tsiviilehituslikud rauast liivavalu osad

Alates ettevõtte loomisest on Maple Machinery Iron Sand Casting Parts spetsialiseerunud kvaliteetsete ja keerukate raudvalandite tootmisele paljudele tööstusharudele alates esimesest päevast. Pakume oma klientidele alumiiniumkomponentide terviklahendusi. Teostame oma organisatsioonis iga keeruliste valandite valmistamisega seotud alamprotsessi. See tagab tervikliku ehitustehnilise rauast liivavaluosade lahenduse, kus kliendid saavad kasu suurepärasest kvaliteedist ja usaldusväärsusest, mida neil on õigus oma raudliivavalu osade tarnijatelt oodata.Nafta- ja gaasitööstuse terasest suletud stantsitud osad

Maple machinery on ettevõte, mis on sepistamislahendusi pakkunud viimased 20 aastat. Oleme läbinud ISO9001 sertifikaadi. Nulldefekt on osa meie tootmisstandarditest ja tagame, et kõiki protsesse hoitakse majasiseselt esmaklassilise infrastruktuuriga. Oleme uhked oma kogemuste ja tarnijatega avatud suhtlemise üle, et arendada nafta- ja gaasitööstuse terasest suletud stantsitud osi, vastata klientide disainistandarditele ja pakkuda kvaliteetsete toodete kiiret tarnimist.Taaskasutustööstuse terasevalu osad

Maple Machinery on valuterase tarnija. "Kadunud vaha" meetodit kasutatakse keerukate valandite valmistamiseks väga suure täpsusega. Selle üldise lähenemisviisi tulemusel on meie inseneridel märkimisväärne vabadus toote kujundamisel, ringlussevõtutööstuse terasvaluosade ja materjalide valikul. See tähendab, et teiega konsulteerides saame toota taaskasutustööstuse jaoks parimaid valandeid, mis vastavad täpselt teie soovidele ja nõuetele. Maple machinery on teie arenduspartner edukaks valamiseks, eesmärgiga saavutada parim valu läbi vastastikuse konsultatsiooni.

Saada päring

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy