Helistage meile

+86-19858305627

Saatke meile e-kiri

sales@maple-machinery.com

Ehitustehnilised terasevaluosad Tootjad

Meie tehas pakub liivavalu, suletud stantsi sepistamist, avatud stantsimist jne. Ekstreemne disain, kvaliteetsed toorained, kõrge jõudlus ja konkurentsivõimeline hind on see, mida iga klient soovib ning seda saame ka teile pakkuda. Võtame kõrge kvaliteedi, mõistliku hinna ja täiusliku teeninduse.

Kuumad tooted

Hüdraulikasüsteemi terasest sepistatud osad

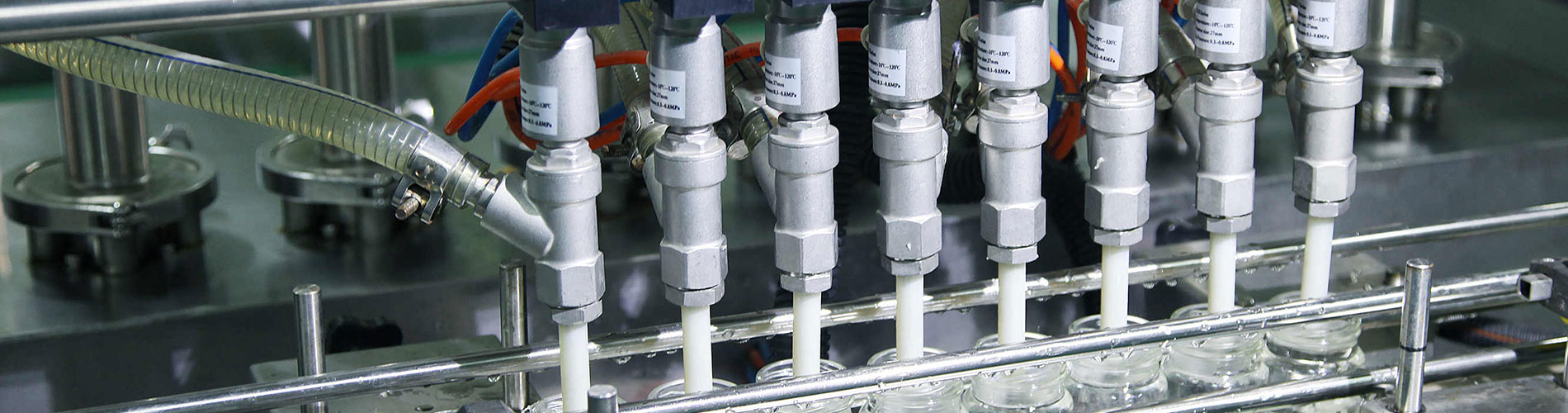

Vahtramasinad on terviklik ja täielikult integreeritud sepistamis- ja töötlemisseade, mis on spetsialiseerunud kohandatud tootmisprojektidele. Süsinikust, legeeritud ja roostevabast terasest hüdraulikasüsteemi terasest sepistamisosad, kaal 0,1–60 kg. Vaher võib vähendada kuumtöötlemise, sepistamise ja tarnimise viivitust ning parandada kvaliteeti.Meresõidukite roostevabast terasest valuosad

Maple machinery is a professional manufacturer located in Ningbo, China. More than 15 years of experience in the steel industry. Our products mainly include Marine Stainless Steel Casting Parts. Our products have been exported to many countries in Europe and America. We have a wealth of foundry experience, but also a number of stable Marine industry customers.产品内容 Product Introduction Maple machinery offers a wide range of custom Marine Stainless Steel Casting Parts. Stainless steel is resistant to corrosion and heat, has aesthetic appeal and low life cycle cost, is fully recyclable and has a good strength-to-weight ratio. We offer austenite, ferrite, martensite and biphase grades: we have hot or cold rolled and various surface treatments such as bright annealing. You can count on our experience. 2. Product Parameter (Specification) Item Marine Stainless Steel Casting Parts Roughness Ra 1.6 Tolerance ±0.01mm Material Casting Steel Certification ISO 9001:2015 Weight 0.01-2000KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Investment Casting Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Service for Marine Maple machinery has been the most demanding supplier of Marine Stainless Steel Casting Parts for more than 15 years. Our reputation has earned us partners and valued customers who follow the most stringent requirements in terms of microstructure integrity, dimensional tolerances and quality control. Our products meet customers' requirements and standards. 4.Supporting Service for Marine As mentioned above, in order to work in adverse conditions, the performance of the Marine Stainless Steel Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Mining Industry We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Marine Stainless Steel Casting Parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for The Marine We have manufactured a wide range of Marine Stainless Steel Casting Parts. The following are typical products: Ground engaging tools: drill bits, carbide tipped tool, forged bucket tooth, auger.... 6.Why Investment Casting Investment casting is a leading process used for the production of high-quality castings and is used to make metal alloys. The key advantage of the investment casting process is that it can help to cast metals with high melting temperatures and create parts with complex geometry that are much needed in industries like aircraft, automotive, and military. As professional investment casting manufacturer, our specialized technique is widely applied to get heavier, stronger, and complex shapes for investment castings. When you trade with us, you get several benefits such as lower costs, a cheaper molding process for complex designs, and higher accuracy. Another competitive benefit enjoyed by Maple Machinery is its leading position in China for casting technology. We will provide precision castings and micron-level processing services.Kaevandustööstuse kõrgtugevast malmist valuosad

Alates selle loomisest on Maple teeninud maine võrratu klienditeeninduse poolest. Meilt leiate kõik mäetööstuse kõrgtugevast malmist valuosad. Teenindus on meie eriala ja teeme kõvasti tööd, et tarnida teile vajalikke tooteid just siis, kui neid vajate. Oleme pühendunud kvaliteetsete toodete pakkumisele konkurentsivõimeliste hindadega, et tagada klientide rahulolu.Rasketööstuse terasevalu osad

Vahtramasinatel on üle viieteistkümneaastane kogemus rasketööstuse terasvaludetailide valmistamisel. Me viime läbi iga protsessi pistelise kontrolli ja teostame 100% vahekontrolli. Ja kliendisuhtlus ja suhtlus peab olema õigeaegne ja täpne. Klientidele kohandatud tooted peame olema kõige professionaalsemad. Maple masinate valamisetoodete hulgas toodame täppisvalusid, millel on lai valik rasketööstuse terasvaluosi. Meie terasest, roostevabast terasest ja alumiiniumist investeerimisvalandeid kasutatakse riistvaraturul laialdaselt. Investeerimisvalu protsess on suurepärane valik täpsete mõõtmetega riistvaratoodete tootmiseks. Suur hulk täpse suurusega osi rasketööstuses.2. Toote parameeter (spetsifikatsioon)Nafta- ja gaasitööstuse terasest kadunud vahavalu osad

Maple on suurte kogemustega valu- ja töötlemisettevõte ning meil on suur kindlus, et anname oma parima nafta- ja gaasitööstuse terasest kadunud vahavalu osade osas. Meie Lost Wax Castingi eksperdid aitavad teid kõigi parimate lahendustega. Täitke oma vajadus vajaliku toote järeleKiirteetööstuse kõrgtugevast malmist valuosad

Kui valite Maple masina, valite kogenud kõrgtugevast malmist valuosade tootja, kes suhtub oma erialasse kirglikult. Maple machinery'il on ligi 20-aastane kogemus Off Highway Industry kõrgtugevast malmist valuosade arendamise ja tootmise alal. Kõrgtugeva malmi valamise igal sammul ollakse teadlikud, et kirg ja kvaliteet käivad käsikäes. Nii arenevad kõik iga päev raudselt tugeva meeskonnana.

Saada päring

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy