Helistage meile

+86-19858305627

Saatke meile e-kiri

sales@maple-machinery.com

Täppisvalu nafta- ja gaasitööstusele Tootjad

Meie tehas pakub liivavalu, suletud stantsi sepistamist, avatud stantsimist jne. Ekstreemne disain, kvaliteetsed toorained, kõrge jõudlus ja konkurentsivõimeline hind on see, mida iga klient soovib ning seda saame ka teile pakkuda. Võtame kõrge kvaliteedi, mõistliku hinna ja täiusliku teeninduse.

Kuumad tooted

Nafta- ja gaasitööstuse hallraua valuosad

Alates halli rauavalu inseneridest, tehnikutest, meistridest, mudeliehitusmehaanikutest ja mudeliehitajatest tootmises ning lõpetades tööstuslike mehaanika- ja elektroonikatehnikute või tööstusjuhtimise assistentidega hoolduses, annavad nad iga päev endast parima, et meie nafta- ja gaasitööstuse kliente kvaliteetsete valanditega rõõmustada. Alates nõustamisest ja tellimuste töötlemisest kuni tööde ettevalmistamise ja nafta- ja gaasitööstuse hallmalmvaludetailide tootmiseni ning lõpetades süvatöötlemise ja transpordiga, püüdleme meeskonnana ühise eesmärgi poole: toota keerukaid ja kvaliteetseid hallmalmvalu detaile.Kaevandustööstuse kõrgtugevast malmist valuosad

Alates selle loomisest on Maple teeninud maine võrratu klienditeeninduse poolest. Meilt leiate kõik mäetööstuse kõrgtugevast malmist valuosad. Teenindus on meie eriala ja teeme kõvasti tööd, et tarnida teile vajalikke tooteid just siis, kui neid vajate. Oleme pühendunud kvaliteetsete toodete pakkumisele konkurentsivõimeliste hindadega, et tagada klientide rahulolu.Hüdraulikasüsteemi terasest kadunud vahavalu osad

Maple Machinery investeerib kaasaegsetesse ja keerukatesse seadmetesse, et täita kõik kliendi nõuded hüdraulilise süsteemi terasest kaotatud vahavalu osadele töökindluse, korratavuse ja paindlikkuse osas. Maple machinery'il on laialdased kogemused kaotatud vahavalu ja tööstuslike sertifikaatide alal, mida uuendatakse ja täiustatakse iga kord.Rasketööstuse terasevalu osad

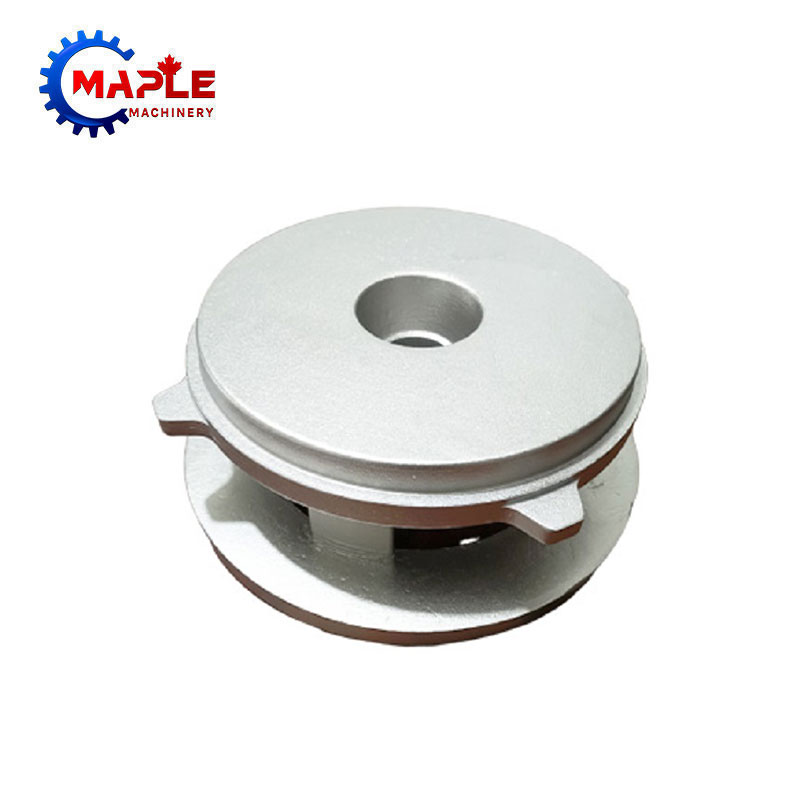

Vahtramasinatel on üle viieteistkümneaastane kogemus rasketööstuse terasvaludetailide valmistamisel. Me viime läbi iga protsessi pistelise kontrolli ja teostame 100% vahekontrolli. Ja kliendisuhtlus ja suhtlus peab olema õigeaegne ja täpne. Klientidele kohandatud tooted peame olema kõige professionaalsemad. Maple masinate valamisetoodete hulgas toodame täppisvalusid, millel on lai valik rasketööstuse terasvaluosi. Meie terasest, roostevabast terasest ja alumiiniumist investeerimisvalandeid kasutatakse riistvaraturul laialdaselt. Investeerimisvalu protsess on suurepärane valik täpsete mõõtmetega riistvaratoodete tootmiseks. Suur hulk täpse suurusega osi rasketööstuses.2. Toote parameeter (spetsifikatsioon)Rasketööstuse terase investeerimisvalu osad

Vahtramasinatel on pikk ajalugu rasketööstuse terase investeerimisvalu osade vallas ning ajaloost ja kaasaegsetest juhtimismeetoditest kogunenud professionaalne tugevus, et saavutada suurepärane täiendavus ja integratsioon. Nüüd on tehnoloogia pideva innovatsiooni ja arengu kaudu jõudnud suure hüppeni.Rasketööstuse terasest sepistatud osad

Vahtramasinad on Hiinas kiiresti kasvav sepistamistoodete pakkuja, kes on keskendunud tänapäevaste sepistamistoodete väljakutsetele. See on olnud edukas alates selle loomisest ja on üks juhtivaid erinevate teraseklasside sepistamise tarnijaid rasketööstusele. Hea mainega kliendid ja testimisagentuurid tunnustavad vahtramasinaid nende kvaliteetsete rasketööstuse terase sepistamisosade poolest. Meie ettevõte on alati keskendunud kõige arenenumale tehnoloogiale, et pakkuda aasta-aastalt paremaid sepistamistooteid.

Saada päring

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy