Tooted

- View as

Klapi terasest suletud stantsitud osad

Pakume kvaliteetseid klapiterasest suletud sepistamisosi, samuti paindlikkust ja vastutust, et vastata nii klapitööstuse kõrgetele nõudmistele kui ka mujale. Olenemata sellest, kas tegemist on klapiosade või muude stantsitud osadega, valmistame neid Maple masinates. Nautige sama kvaliteeti ja kliendikeskset lähenemist. Arendame ja toodame täielikult terasest suletud stantsitud sepiseid

Loe rohkemSaada päringRasketööstuse terasest suletud stantsitud osad

Vahtramasinad on spetsialiseerunud suletud die sepistamisele, valmistades kvaliteetseid rasketööstuse terasest suletud stantsimisosi. Meie tegevusala on globaalne turundus. Praeguseks on ettevõte loonud pikaajalised koostöösuhted paljude tuntud klientidega kodu- ja välismaal. Maple masinate kultuur on luua väärtust enese ärakasutamiseks. Selle suurimad kasusaajad on tema kliendid. Tänu sellele on Maple machinery olnud ja jääb ka edaspidi meie klientidele usaldusväärseks ja pühendunud partneriks.

Loe rohkemSaada päringMereterase sepistamisosad

Peamise metalli sepistamise tüübina on terase sepistamine terase vormimise tehnoloogia, mis kasutab kohalikku survejõudu. Sepised on läbi teinud olulisi muutusi, mis on viinud tõhusamate, kiiremate ja kauem kestvate protsessideni. Tänapäeval valmistatakse mereterasest sepistamisosi tavaliselt elektriliste, hüdrauliliste või suruõhuajamiga sepistamispresside või haamritööriistadega. Kuum sepistamine hõlmab töödeldava detaili kuumutamist umbes 75% sulamistemperatuurist.

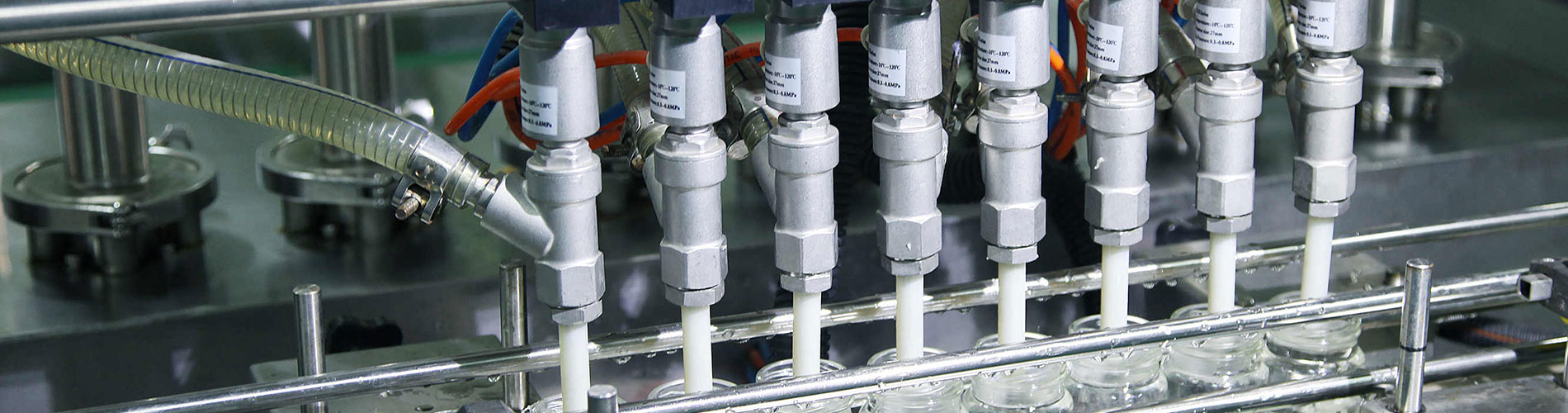

Loe rohkemSaada päringToidutööstuse masinate terasest sepistamise osad

Maple machinery investeerib pidevalt meie inimeste, protsesside ja masinate arendamisse, et saavutada meie arengueesmärke. Investeeringud ja innovatsioon on taganud toiduainete töötlemise masinate terasest sepistamisosade taseme. Tänu pidevale sisemisele arengule ja täiuslikkuse poole püüdlemisele oleme klientide poolt tunnustatud.

Loe rohkemSaada päringKlapi terasest sepistamisosad

We at Maple machinery guarantee the quality and impeccable service of every Valve Steel Forging parts. We strive for excellence every day, using all of our expertise and tremendous commitment to ensure maximum efficiency. We aim at innovation to create a better future and bravely face every new challenge. Product Introduction The different Forging techniques offered by Maple machiney Forging solutions enable us to forge the different Valve Steel Forging parts of valves all of which are designed to the customer's requirements and are also checked and verified in a simulator before forging. The resources and skills of our staff enable us to forge any type of material that is processed on our heat treatment equipment and completed after conducting final destructive and non-destructive tests. They are provided on delivery terms agreed with the customer and include all required documents and certificates. 2. Product Parameter (Specification) Item Valve Steel Forging parts Roughness Ra 1.6 Tolerance ±0.01mm Material Alloy Steel Certification ISO 9001:2015 Weight 0.01-60KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Closed Die Forging Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Services for Valve Our Valve Steel Forging parts have a worldwide reputation for their high quality and reliability. With our state-of-the-art testing laboratories and highly qualified workforce, we combine the highest standards of technology, quality and productivity. Accurate delivery time, fast service, we get the customer's praise. 4.Supporting Service for Valve parts As mentioned above, in order to work in adverse conditions, the performance of the Valve Valve Steel Forging parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Agricultural Machinery We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Valve Steel Forging parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for the Valve We have manufactured a wide range of Valve Steel Forging parts. The following are typical products: Valve joint, Ball valve body, Gate valve body, Choke valve body,Beer valve body,Purification water brass,Hybrid valve, .... 6. Why Closed Die Forging Compared with casting, forging has its special advantages: 1. In the case of the same material, the mechanical properties of forgings are better than those of castings. 2. The forgings strength is higher and the fatigue resistance is stronger. 3. The forgings has better compactness. 4. There are no internal defects and surface defects. 5. Fast production speed, high efficiency, suitable for mass production of products. 6. The product quality is stable.

Loe rohkemSaada päringRasketööstuse terasest sepistatud osad

Vahtramasinad on Hiinas kiiresti kasvav sepistamistoodete pakkuja, kes on keskendunud tänapäevaste sepistamistoodete väljakutsetele. See on olnud edukas alates selle loomisest ja on üks juhtivaid erinevate teraseklasside sepistamise tarnijaid rasketööstusele. Hea mainega kliendid ja testimisagentuurid tunnustavad vahtramasinaid nende kvaliteetsete rasketööstuse terase sepistamisosade poolest. Meie ettevõte on alati keskendunud kõige arenenumale tehnoloogiale, et pakkuda aasta-aastalt paremaid sepistamistooteid.

Loe rohkemSaada päring